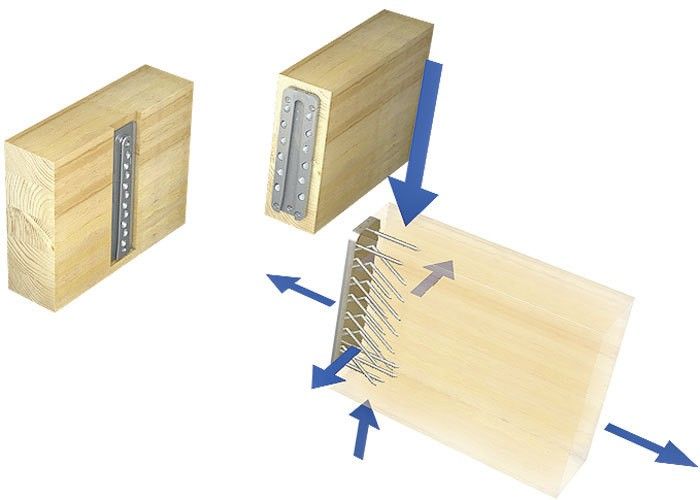

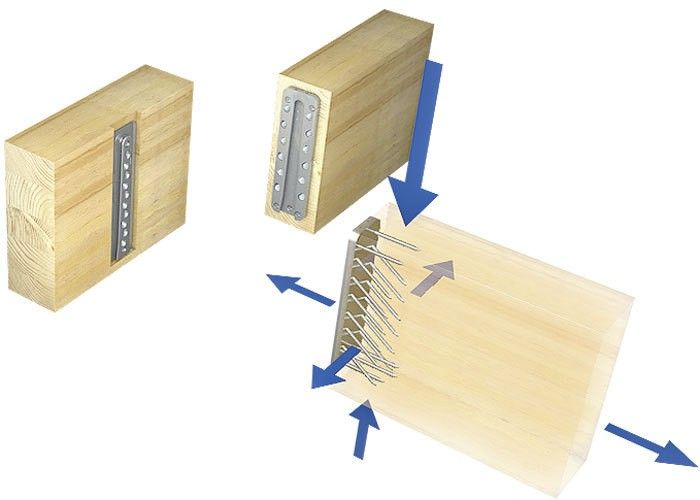

The advance of CLT is so triumphant also because the accessories are becoming more and more powerful. This is especially true for the connecting means. In cooperation with the Technical University of Graz/AT and the University of Innsbruck/AT, Sherpa Connection Systems, Frohnleiten/AT, has put lot of development effort in the connection means for CLT. The connection of solid wood elements is challenging because usually high load levels meet with lower screwing depths.

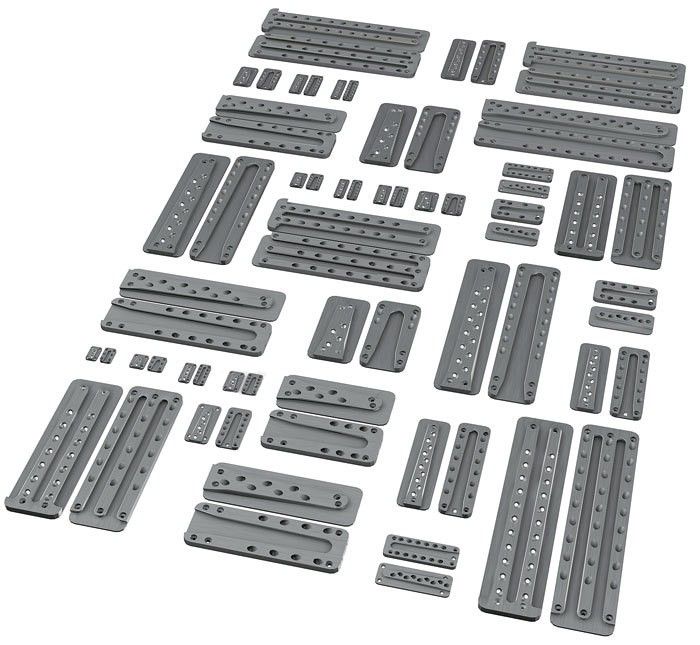

33 types of connectors for wood to wood

The portfolio of the company which belongs to the Vinzenz Harrer group is comprehensive. Following the latest European Technical Approval on May 23 (ETA-12/0067), sales engineer Joseph Kowal can now draw from a range of 58 Sherpa connector types. 33 products for wood to wood-connections are grouped into five series (XS to XXL). For wood to steel- and wood to reinforced concrete-connections, Sherpa offers 25 types in three series (M to XXL). "Despite the diversity, all the connectors are based on the same principle", said Kowal. To mount the port to the wood, the experts in Frohnleiten have come up with special Sherpa-screws with reinforced heads for optimal power transmission. Measuring from 8 mm nominal diameter and higher, they have a pre-drilling half point tip for more "bite" and less wood splitting risk. "With Sherpa, no screw must be pre-drilled", says Kowal highlighting the system's high processing speed. Only for the position of holes in automated manufacturing a drill must go into the wood prior to mounting. This way, timber construction companies save the effort for measuring and marking. Connection to steel and concrete is achieved by special bolts used in steel structures or concrete screws with metal expansion anchors. For this purpose, Sherpa recommends screw MMS-F manufactured by Heco, Schramberg/DE.Simple solutions are safe solutions

Sherpa connector of the L series will take on large loads of up to 80 kN. It was developed specifically for CLT and thus can be used in three-layered elements of 10 cm minimum thickness © Sherpa

"We have designed the L series particularly for CLT constructions", says Kowal. These connectors are mounted with system screw 8 x 100 mm and are therefore suitable for CLT of 10 cm thickness. They are typically used for attaching glulam ceiling joists on walls, featuring a load bearing capacity of 30 to 80 kN.

Sherpa's CLT solutions are the subject of several research projects. At the Competence Centre holz.bau Forschungs GmbH (HBF) and the Lignum Test Center at the Technical University of Graz, the connectors were tested on CLT elements last year. In addition, the structural behavior under torsion stress and lifting forces was analyzed. "This means that virtually all installation situations can be calculated with Sherpa", concludes HBF-representative Manfred Augustin. And the next research project is already close to completion (see box below). <

New CLT-wall connectors developed

Sherpa Connection Systems and the faculty of timber construction at the University of Innsbruck have developed a new connector for CLT. The results are yet to be published in the research media. So Sherpa cannot reveal accurate data here. The following advantages should help the CLT-connector to increase the competitiveness of solid wood construction in relation with other materials:- Quality assurance through standardization – the position and number of the connecting means are determined by prefabrication.

- Defined anchor points facilitate exact positioning of the components.

- On-site assembly is done from the inside. This allows a higher degree of prefabrication during wall construction. Scaffolding work is made redundant.

Pilot projects are already underway. The official launch in Austria is coming up soon. At the International Forum for Timber Construction in Garmisch-Partenkirchen/DE in December, the CLT connector will be presented to the experts by faculty member Josef Kögl. Involved in the development was the team around Univ. Michael Flach and Dr. Anton Kraler of the faculty of timber construction at the University Innsbruck, as well as Martin Obermayr (Vinzenz Harrer's sales manager), Joseph Kowal (sales engineer at Sherpa Connection Systems) and company founder Vinzenz Harrer. <